User’sManualforAuto-TuningUltrasonicGenerator

User’sManualforAuto-TuningUltrasonicGenerator

Contents

SafetyandWarning………………………………………………..…1

IntroductiontoSmartgenerator.…………………………………..…2

Technical Parameters…………………..……………………………3

Installation…………………………………..…………………………4

OperationalManual……………………………………………..……5

User’sManualforAuto-TuningUltrasonicGenerator

User’sManualforAuto-TuningUltrasonicGenerator

`

.Safety andWarnings

Thissectiondescribesthesafetyandcautionsymbolsandits

meanings,andprovidesthenormalsafetyandpreventionmethodsfor

ultrasonicgenerators.

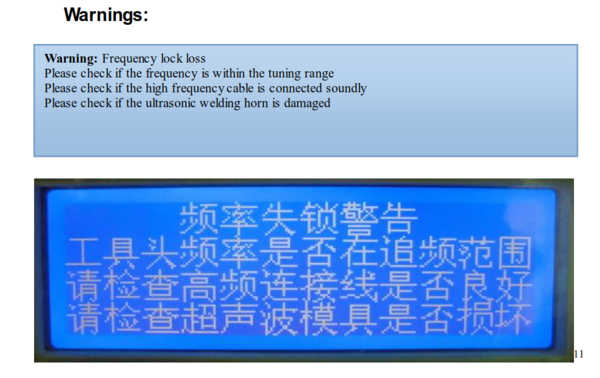

“Warning”indicatesthepotentialdangers,whichwillcausevarious

damageorinjury ifitisneglected.

Thefollowingpreventionmeasuresmustbetakenbeforehandlingthe

ultrasonicgenerator:

ThePowershouldbeinOFFpositionbeforeconnectinganyelectrical

parts.Thepowerplugmustbeequippedwithgroundingterminalsto

avoidanyelectricaccident.

Theultrasonicgenerator willproducehighvoltage,sothefollowing

stepsmustbeobservedbeforehandlingit:

Poweroff;

Takeofftheplugofthemajorpowersupply;

Wait2minutestomakethecapacitorreleasethepowercompletely.

Theremaybehighvoltageinsidetheultrasonicgenerator,soonly

professionalpersonnelisallowedtoopenitshousing.

Astheremaybehighvoltageintheultrasonicgenerator,anditshigh

voltageGNDisnotconnectedtotheground,sopleaseusethe

universalmeterwhichisnotgroundedbutsupplied bybatteriesduring

test.Othermethodsmaycauseelectricshock.

Pleasedonotputyour handundertheweldinghorn,which

maycauseinjury duetothedownwardspressureand

ultrasonicvibration.

Whenthehighfrequencycablesorthetransducerisdisconnected,

pleasedonotexecutetheweldingandtestingaction.

Whenbigweldinghornisused,pleasedonotputyour fingersbetween

thehornandthe fixture.

User’sManualforAuto-TuningUltrasonicGenerator

User’sManualforAuto-TuningUltrasonicGenerator

`

Thismodelmustbeoperatedbyaspecifiedperson.Operation

andcommissioningbymorepeopleisprohibited.

2.IntroductiontoSmartUltrasonicGenerator

Ultrasonicsignalgeneratorconsistsofanultrasonicpoweramplifying

modulethatcanconvertthe50/60HzindustrialACpowerinto

ultrasonicfrequencyanda controlmodulethathas“systemprotection

inspection”functionand“auto-tuning”function.Thecontrolmodulecan

cutthepowersupplywhenthereisanymalfunctionduringultrasonic

weldingprocess,thusmakingasaferandmorereliablegeneratorand

eventhewholeweldingmachine.

1)Reallyfullyauto-tuning(AFC)canbeapplicablefor

weldinghornsindifferentsizesanddesigns,andthe

auto-tuningrangeis±400HZ.Taking15Khzultrasonic

generatorforexample,the weldinghornfrequencyrangeis

14.40-15.20KHZ,auto-tuning).Auto-tuningprecisionis

±5HZ.

2)ComputerwithCPUisusedtomonitortheprocess,which

isquickandflexible,andithasvariousbuilt-inprotection

systems.The“systemprotectionandmonitoring”function

will reacttothefollowingconditions:

uover-heatprotection

uExcessivepressurethatcausedover-load

uExcessivecurrentinthe ultrasonicgenerator

uAnylooseningoftheweldinghorn,boosterorconverterorany

othermalfunction.

uGeneratorelectricalcircuitfailure

uFailureofthecablesthatconnectthegeneratorandtheconverter.

uAutocompensationforUnstablepower supply,.

3)Auto-tuningfunctionenablestheultrasonicgeneratortraceand

compensatethe differenceofweldinghornfrequencyautomatically.When

User’sManualforAuto-TuningUltrasonicGenerator

User’sManualforAuto-TuningUltrasonicGenerator

`

thetemperatureistoohigh,thehornsurfacewillbedamagedduetothe

abrasionorsomematerialssticktothehorn,underthiscondition,the

frequencyofthehornwillchange.

4)Built-in,fullyautomaticconstantamplitudesystemwillgiveautomatic

compensationtothefluctuationofairpressureandelectricalvoltage,

whichcanadjusttheamplitudewithintherangeof50%-100%tomeet

demandofdifferentparts.

5)IGBTisusedtoamplifythepower,whichreactsquickly,and100times

quickerthantraditionalsiliconpowertubes,soithasabetterperformance.

3.MainTechnical Parameters

Size:L380mm×W290mm×H110mm

Net Weight:7Kg

Outputpower:0-3000W

Outputvoltage:0-3000VAC

Workingenvironmenttemperature:+5°C至+50°C

SineHarmonicwave:≥97%

Inputpowerfactor:≥80%

Workingfrequency:15KHz/20KHz/28KHz/30KHZ/35KHz/40KHz

Workingpowersupply:AC220V50Hz

Weldinghornfrequencyscope:±400HZ(for15KHZgenerator,

theweldinghornfrequencyis14.40-15.20KHZ,auto-tuning)

Auto-tuningprecision:±5HZ

Powerstability:≤5%

Remoteterminal dynamicreactiontime:≤10ms

Over-currentprotectionlimit:15A

Over-current protectiontime:100ms

Over-heatprotectiontemperature:85℃

4.InstallationConditions

For more instructions of ultrasonic welding machine in English, please move

https://7310099.s21i.faiusr.com/61/ABUIABA9GAAgmZiphwYotZrS-wQ.pdf

恒波超聲波設(shè)備0755-28993510http://rocketprojector.com